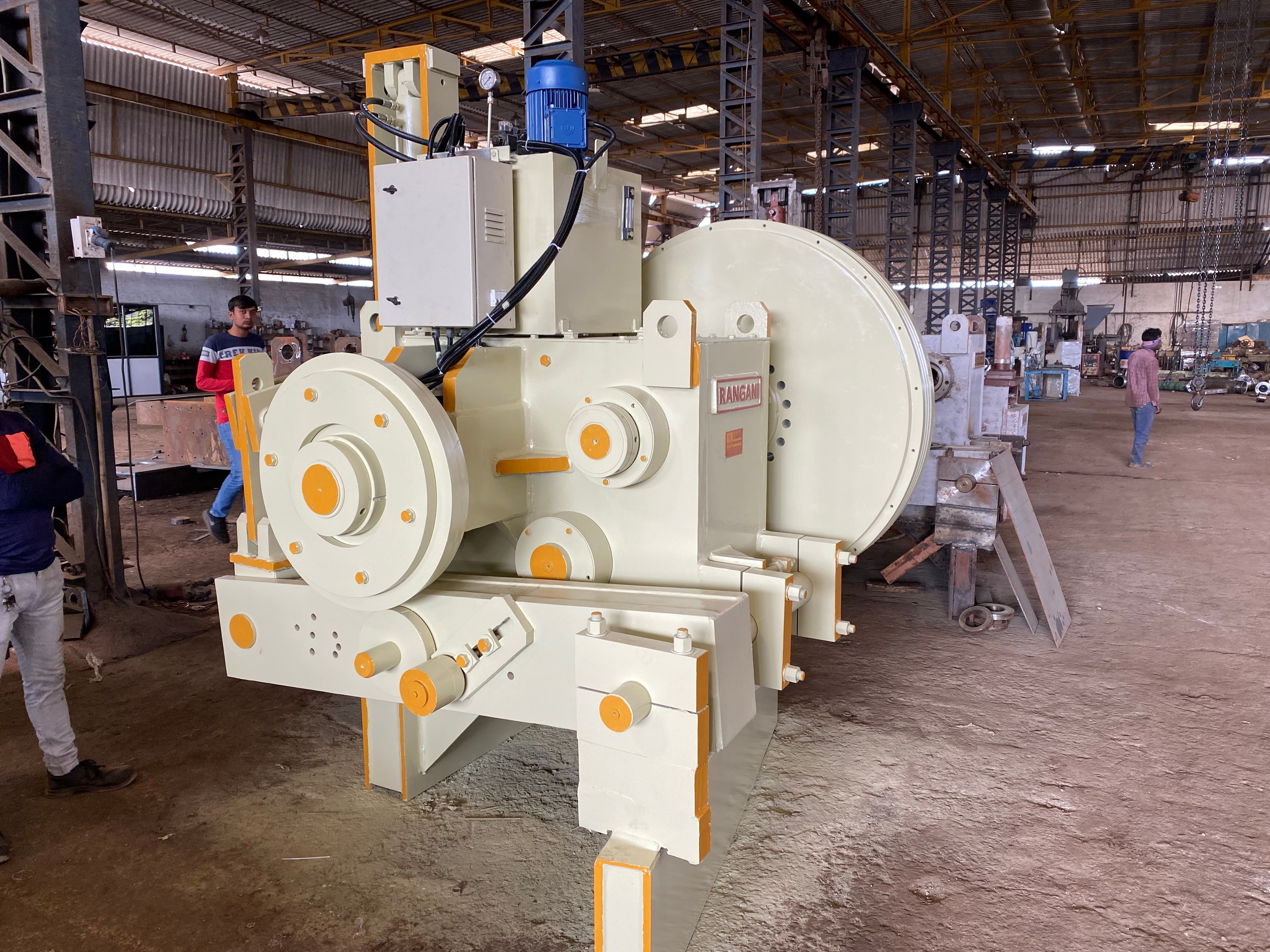

Forging Ring Rolling Machine

MOQ : 1 Unit

Forging Ring Rolling Machine Specification

- Features

- Robust construction, high precision, easy maintenance, efficient productivity

- Drive

- Hydraulic

- Lubricating System

- Automatic lubrication

- Operating Temperature

- Up to 1250C

- Production Capacity

- 1-10 pcs/hour

- Cooling System

- Water/air cooling optional

- Noise Level

- <80 dB

- Control System

- PLC Based

- Frame Type

- Heavy-Duty Welded Steel

- Motor Power

- 45 kW

- Power Rating

- 50 kW

- Accuracy

- 0.5 mm

- Machine Type

- Horizontal Ring Rolling

- Model No

- FRRM-6500

- Frequency

- 50/60 Hz

- Connectivity Options

- Ethernet, USB

- Voltage

- 380-415 V

- Product Type

- Forging Ring Rolling Machine

- Technology

- Hot Forging

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 50 kW

- Pressure

- Up to 4500 kN

- Surface Treatment

- Painted / Anti-corrosive coating

- Dimension (L*W*H)

- 6500 x 3400 x 3600 mm

- Weight (kg)

- Approx. 15,000 kg

- Color

- Industrial Blue / Grey

- Usage & Applications

- Industrial

Forging Ring Rolling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 4 Units Per Month

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia, Africa, Western Europe, Australia, Central America, Middle East, North America, South America, Eastern Europe

- Main Domestic Market

- All India

About Forging Ring Rolling Machine

Discover our rare FRRM-6500 Forging Ring Rolling Machine, impressively engineered for instant checkout in clearance sales. Featuring a towering frame of heavy-duty welded steel, the machine supports imposing ring diameters from 300 mm to 2500 mm and thicknesses from 20 mm to 300 mm. Its remarked alloy steel rollers and hydraulic forging force up to 4500 kN deliver exceptional precision, fast cycle times, and high productivity. Advanced PLC-based controls, integrated safety features, and a touchscreen HMI promise superior usability in demanding industrial environments.

Advantages, Usage & Application Places

The Forging Ring Rolling Machine delivers high precision, efficient productivity, and reliable operation across diverse industries. Its adjustable working speed and support for custom ring shapes enhance versatility. Ideal for steel mills, forging plants, and heavy equipment manufacturers, it is perfect for producing round, oval, or bespoke rings from steel, alloy, or stainless steel. Its robust design and rapid cycle time make it indispensable for automotive, railway, wind energy, and construction sectors.

Domestic Market, Sample & Payment Terms

Primarily shipped across major industrial zones in India, the Forging Ring Rolling Machine is well-supported in the domestic market. Sample units can be provided upon request to help evaluate operational expenditure before bulk investment. Quotations are shared promptly for manufacturers, exporters, suppliers, and wholesalers. Payment terms are flexible, with options tailored for industry standards, ensuring a smooth purchasing experience from enquiry to installation.

Advantages, Usage & Application Places

The Forging Ring Rolling Machine delivers high precision, efficient productivity, and reliable operation across diverse industries. Its adjustable working speed and support for custom ring shapes enhance versatility. Ideal for steel mills, forging plants, and heavy equipment manufacturers, it is perfect for producing round, oval, or bespoke rings from steel, alloy, or stainless steel. Its robust design and rapid cycle time make it indispensable for automotive, railway, wind energy, and construction sectors.

Domestic Market, Sample & Payment Terms

Primarily shipped across major industrial zones in India, the Forging Ring Rolling Machine is well-supported in the domestic market. Sample units can be provided upon request to help evaluate operational expenditure before bulk investment. Quotations are shared promptly for manufacturers, exporters, suppliers, and wholesalers. Payment terms are flexible, with options tailored for industry standards, ensuring a smooth purchasing experience from enquiry to installation.

FAQs of Forging Ring Rolling Machine:

Q: How does the Forging Ring Rolling Machine benefit industrial operations?

A: This machine combines robust construction and high precision, allowing for efficient production of rings in various shapes and materials, thereby increasing productivity and reducing manufacturing errors.Q: What types of rings can be produced using this machine?

A: It supports the production of round, oval, and custom ring shapes with diameters ranging from 300 mm to 2500 mm and thicknesses from 20 mm to 300 mm.Q: Where is the Forging Ring Rolling Machine typically used?

A: It is widely utilized in industrial sectors such as metal forging plants, steel mills, automotive, railway, wind energy, and construction industries.Q: What is the process for ordering and receiving the machine?

A: After requesting a quotation, payment terms are agreed upon. The machine is then shipped promptly to your site, with sample units available for preliminary evaluation.Q: How is safety ensured during machine operation?

A: Safety is secured through integrated emergency stop switches, robust frame construction, automatic lubrication, and advanced PLC control systems for reliable operation.Q: What are the main maintenance features of the machine?

A: The machine includes automatic lubrication and efficient cooling systems, which contribute to easy maintenance and sustain prolonged reliable performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Forging Ring Rolling Machine Category

Ring Rolling Machine

Minimum Order Quantity : 1 Unit

Product Type : Other, Ring Rolling Machine

Power Source : Electric, Other

Operating Type : Automatic

Usage & Applications : Industrial

Power : 2 5 Horsepower (HP)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS